On-Line pH Measurement

Additional Information

Beer drinkers are interested in unique flavors and profiles. To be successful brewers must deliver distinctive but consistent brews. Measuring pH consistently ensures that the iconic beer comes out perfect every time

BIOCHEMICAL PROCESSES– Success in brewing is dependent on biochemical processes that impact beer’s flavor, profile, and alcohol content. Consistently monitoring these processes ensures a quality beer after each brew. pH measurements can indicate the biochemical processes are occurring according to plan in a given batch. Examples are maintaining an appropriate pH level during mashing to encourage proper enzyme activity effecting the production of fermentable sugars. The adjustment of the water pH to the optimal range for enzymatic activity (usually about 5.2-5.5), ensures the proper amount of sugars will be produced.

FERMENTATION – Measuring beer pH during fermentation can be an early indicator of problems. Some problems for example can be, if a batch becomes infected with undesirable acid producing bacteria, the pH of the mixture will drop below the normal range.. An increase in beer pH can be an indicator of autolysis when yeast cells die and break apart.

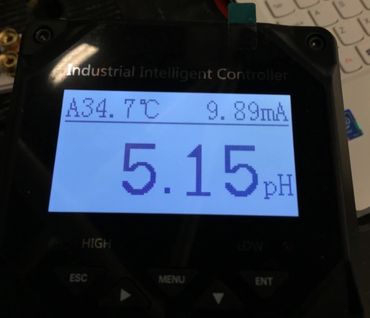

ON-LINE PH MEASUREMENT - Due to tradition and cost concerns the measurement of pH is a manual process. The benefits of on-line pH measurement are reduced labor and real time data to quickly identify problems for corrective action.

IBT SOLUTION – IBT offers an affordable pH sensor and transmitter that is ideal for mounting in-line and can handle the high temperature associated with the production of wort.

Evaluate On-line pH Measurement

Experience the ease and simplicity of on-line pH measurement.

Photo Gallery